Products description:

The main purpose

The metal spiral wound gasket with excellent resilience can carry out pressure thermal cycling and vibration of the pipeline system

Automatic adjustment, especially suitable for occasions where the load is uneven, the joint force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. Is the valve

The static sealing elements at the flange joints of doors, pumps, heat exchangers, towers, manholes, hand holes, etc., are widely used in petrochemical, machinery, electric power, metallurgy, manufacturing

Shipbuilding, medicine, atomic energy and aerospace departments.

In the design of flange gasket, for the convenience of installation, 2~8 positioning belts are welded on the periphery of the gasket according to the diameter of the gasket, so that the positioning belt is buckled on the flange.

On the hole, to prevent the gasket from shifting or falling off during installation, saving auxiliary materials and man-hours. Generally divided into the following types:

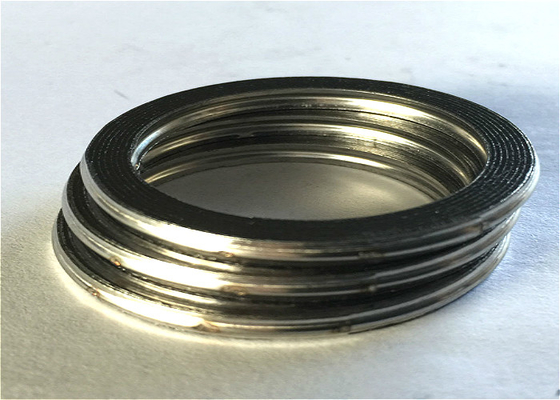

Metal spiral wound gaskets are made of high-quality SUS304, SUS316 ("V" or "W" shape) metal belts and other alloy materials with graphite, asbestos, poly

Soft materials such as tetrafluoroethylene gasket and non-asbestos are alternately overlapped and spirally wound with each other, and the metal tape is fixed by spot welding at the beginning and the end.

Metal spiral wound gaskets are semi-metallic gaskets with good resilience. The structure density of metal spiral wound gaskets can be made according to different locking force requirements.

The inner and outer steel rings are used to control the super tightness, and the surface accuracy of the flange sealing surface contacted by the wound gasket is not high. Metal wound gasket

The sheet is especially suitable for occasions where the load is uneven, the joining force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. Spiral wound gasket is a valve

Flanges such as doors, pumps, heat exchangers, towers, manholes, hand holes, etc.

Application range of spiral wound gasket:

Pipes, valves, pressure vessels, condensers, heat exchangers, towers, manholes, hands in petroleum, chemical, metallurgical, electric power, shipbuilding, machinery and other industries

The flange joints such as holes are sealed.

Types of spiral wound gaskets:

Type, Section, Code, Thickness, Basic Spiral Wound Gasket A3.24.5 Wound Gasket with Inner Ring B 4.5 Wound Gasket with Outer Ring C 4.5 Wrapped with Inner and Outer Ring

Wound gasket D 4.5

The structure material of metal spiral wound gasket:

Filling material Steel belt Inner ring Outer ring

Asbestos winding SUS 304 carbon steel carbon steel

Graphite winding SUS 316 SUS 304 SUS 304

PTFE winding SUS 316L SUS 316 SUS 316

SUS 316L SUS 316L

Filling material temperature (°C) extra large operating pressure (kg/cm2)

Graphite winding -200~550 250

Asbestos entanglement -150~450 100

PTFE winding 240~260 100

The following table is used to select the material of the inner ring and the winding metal:

Product name AISI Hardness (HB/HV) Temperature (°C)

Stainless steel 304 304 130~180 -250~+550

Stainless steel 316 316 130~180 -100~+550

Stainless steel 316L 316L 130~190 -100~+550

The outer ring is usually composed of carbon steel treated with corrosion protection.

Flange type and spiral wound gasket form:

Flange type spiral wound gasket shape flat flange with outer ring wound gasket only with inner and outer ring wound gasket convex face flange only with outer ring wound gasket with inner and outer ring

Spiral Wound Gasket Concave and Convex Flange Basic Spiral Wound Gasket only with inner ring wound gasket groove flange Basic Wound Gasket only with inner ring wound gasket plane and groove

Flange basic type spiral wound gasket only with inner ring wound gasket thickness tolerance of spiral wound gasket:

Item thickness (mm) Tolerance (mm) Gasket thickness 4.5, 3.2+0.2

-0.1 ring thickness 3.0±0.24 metal spiral wound gasket main technical parameters:

The coefficient of spiral wound gasket m=2.5-4 The use pressure of spiral wound gasket ≤25MPa The use temperature of spiral wound gasket -196℃-700℃ (not in oxidizing medium

Above 600℃) Spiral Wound Gasket Extra small preload pressure y=68MPa The following table is the diameter tolerance of Wound Gasket (namely the nominal pipe diameter used for flange)

DIM(mm) ANSI B16.5BS1560(mm) Mss sp-44API605 tolerance inner ring inner diameter gasket inner diameter

<=600<=24">=26" and <=34"±0.5>600 and <=800>24" and <=34>=36" and <=60"±0.9>800 and <=1600 >34 "and <=60" ±1.3>1600>60" ±1.6 Gasket outer diameter<=600<=24"<=24"±0.9>600 and <=160000 >24" and <=60" ±1.81600>60 "±2.2 Outer ring outer diameter>1/2" and <=60"±0.9<=600<=24" 0-1.0 >600 and <=1000>24" and <=34" 0-1.8>1000 and < =1600>34" and<=60" 0-2.2 Note: In addition, we can also produce according to JIS, JPI standards or customer requirements

Ordering instructions: The following parameters should be indicated when ordering metal wound gaskets, examples:

1. Type of metal wound gasket: A B C D

2. Flange standard: ASME B16.20

3. Pipeline diameter and pressure rating: 2" 150Lbs

4. Material type: inner ring SS316; metal winding belt SS316; packing belt: graphite; outer ring: carbon steel

※ The actual application conditions are different, the above parameters are for reference only and do not make any guarantee requirements.

Application range of spiral wound gasket:

Pipes, valves, pressure vessels, condensers, heat exchangers, towers, manholes, hands in petroleum, chemical, metallurgical, electric power, shipbuilding, machinery and other industries

The flange joints such as holes are sealed.

Types of spiral wound gaskets:

Type, Section, Code, Thickness, Basic Spiral Wound Gasket A3.24.5 Wound Gasket with Inner Ring B 4.5 Wound Gasket with Outer Ring C 4.5 Wrapped with Inner and Outer Ring

Wound gasket D 4.5

The structure material of metal spiral wound gasket:

Filler Steel belt Inner ring Outer ring

Asbestos winding SUS 304 carbon steel carbon steel

Graphite winding SUS 316 SUS 304 SUS 304

PTFE winding SUS 316L SUS 316 SUS 316

SUS 316L SUS 316L

Filling material temperature (°C) large operating pressure (kg/cm2)

Graphite winding -200~550 250

Asbestos entanglement -150~450 100

PTFE winding 240~260 100

The following table is used to select the material of the inner ring and the winding metal:

Product name AISI Hardness (HB/HV) Temperature (°C)

Stainless steel 304 304 130~180 -250~+550

Stainless steel 316 316 130~180 -100~+550

Stainless steel 316L 316L 130~190 -100~+550

The outer ring is usually composed of carbon steel treated with corrosion protection.

Flange type and spiral wound gasket form:

Flange type spiral wound gasket shape flat flange with outer ring wound gasket only with inner and outer ring wound gasket convex face flange only with outer ring wound gasket with inner and outer ring

Spiral Wound Gasket Concave and Convex Flange Basic Spiral Wound Gasket only with inner ring wound gasket groove flange Basic Spiral Wound Gasket only with inner ring wound gasket plane and groove

Flange basic spiral wound gasket only with inner ring wound gasket thickness tolerance of spiral wound gasket:

Item thickness (mm) Tolerance (mm) Gasket thickness 4.5, 3.2+0.2

-0.1 ring thickness 3.0±0.24 metal spiral wound gasket main technical parameters:

Wound gasket coefficient m=2.5-4 Wound gasket use pressure ≤25MPa Wound gasket use temperature -196℃-700℃ (not high in oxidizing medium

(At 600℃) Spiral Wound Gasket Extra small pre-tightening pressure y=68MPa The following table is the diameter tolerance of Wound Gasket (namely the nominal pipe diameter used for flange)

DIM(mm) ANSI B16.5BS1560(mm) Mss sp-44API605 tolerance inner ring inner diameter gasket inner diameter

<=600<=24">=26" and <=34"±0.5>600 and <=800>24" and <=34>=36" and <=60"±0.9>800 and <=1600 >34 "and <=60" ±1.3>1600>60" ±1.6 outside diameter of gasket

<=600<=24"<=24"±0.9>600and <=160000 >24" and <=60" ±1.81600>60" ±2.2 outer ring

Outer diameter >1/2" and <=60"±0.9<=600<=24" 0-1.0 >600 and <=1000>24" and <=34" 01.8>

1000 and <=1600>34" and <=60" 0-2.2 Note: In addition, we can also produce according to JIS, JPI standards or customer requirements

Ordering instructions: The following parameters should be indicated when ordering metal wound gaskets, examples:

1. Type of metal wound gasket: A B C D

2. Flange standard: ASME B16.20

3. Pipeline diameter and pressure rating: 2" 150Lbs

4. Material type: inner ring SS316; metal winding belt SS316; packing belt: graphite; outer ring: carbon steel

※ The actual application conditions are different, the above parameters are for reference only and do not make any guarantee requirements.

Use of:

1. The use of Temperature: -196°C-650°C 1, the use of Temperature: -196 °C -650 °C

(The oxidation medium does not exceed 450 ° C) Oxidation medium does not exceed 450 ° C)

2. The use of pressure ≤ 26MPa 2, the use of pressure ≤ 25MPa

3. Gasket thickness: 2.5-4.5mm 3, gasket thickness:2.5-4.5 mm

Sexual energy:

1. Wide application range. Can withstand high temperature, high pressure and adapt to ultra-low temperature or use under vacuum.

2. Strong application compensation ability. In the working position where high temperature and high pressure fluctuate frequently, the sealing performance is stable and the reliability is strong.

3. It has good sealing performance.

4. Easy to use and install.

technical parameter

edit

Winding gasket coefficient m=2.5-4

Spiral wound gasket use pressure ≤25MPa

Spiral wound gasket operating temperature -196℃-700℃ (not higher than 600℃ in oxidizing medium)

Spiral wound gasket extra small pre-tightening specific pressure y=68MPa

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!