Molding Process:

|

|

|

|

|

|

|

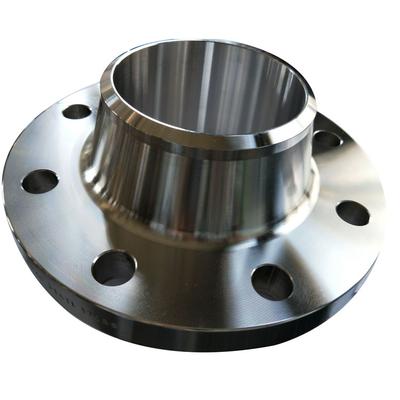

WN/LWN/SO/Blind/Lap Joint

|

150#-2500#

|

1/2"-24"(Except Blind Flange 2500lb 1/2"-12")

|

|

SW flange

|

150#-1500#

|

1/2"-3"(Except 1500# 1/2"-2 1/2")

|

|

Threaded

|

150#-900#

|

1/2"-24"

|

|

1500# 2500#

|

1/2"-2 1/2"

|

|

|

WN/blind flange

|

150# -900#

|

22"-48"(Except 900# Size:26"-48")

|

|

|

WN/blind flange

|

75#-300#

|

26"-48"

|

|

400# 600# 900#

|

26"-36"

|

|

DIN2527

|

Blind flange

|

PN6-PN100

|

DN10-DN1000

|

|

DIN2543

|

SO flange

|

PN16

|

DN10-DN1000

|

|

DIN2544

|

SO flange

|

PN25

|

DN10-DN1000

|

|

DIN2545

|

SO flange

|

PN40

|

DN10-DN500

|

|

DIN2565

|

Threaded flange with Neck

|

PN6

|

DN6-DN200

|

|

DIN2566

|

Threaded flange with Neck

|

PN16

|

DN6-DN150

|

|

DIN2567

|

Threaded flange with Neck

|

PN25 PN40

|

DN6-DN150

|

|

DIN2568

|

Threaded flange with Neck

|

PN64

|

DN10-DN150

|

|

DIN2569

|

Threaded flange with Neck

|

PN100

|

DN10-DN150

|

|

EN1092-1:2002

|

Plate flange for welding/loose plate flange with weld-on plate collar or for lapped pipe end/Blind Flange/WN flange

|

PN2.5-PN100

|

DN10-DN4000

|

|

JIS B2220

|

Welding flange, lap joint flange, threaded flange

|

PN6-PN100

|

DN10-DN1500

|

|

BS4504 BS10 TableD/E

|

Plate Flange for welding/WN flange/blank Flange

|

PN6-PN100

|

DN10-DN1500

|

|

Other Products

|

Anchor/swivel/girth/lap joint/reducing/orifice

|

|

Spectacle blind/paddle blind/spacer ring/orifice plate/bleed ring

|

|

Special Products: rings/forgings/disc/shaft sleeves

|

|

Sealing Surface

|

RF FF RTJ TF GF LF LM

|

|

Flange Face Finish

|

Stock finish/spiral serrated/concentric serrated/smooth finish(Ra 3.2 and 6.3 micrometers)

|

|

125-250 AARH(it is called smooth finish)

|

|

250-500 AARH(it is called stock finish)

|

|

Coating

|

Vanish, yellow paint, anti-rust oil, galvanizing etc

|

|

|

Nickel Alloy Steel

|

ASTM/ASME B/SB564 UNS N02200(NICKEL 200), UNS N04400(MONEL 400),

|

|

UNS N08825( INCOLOY 825), UNS N06600(INCONEL 600),

|

|

UNS N06601(INCONEL 601), UNS N06625(INCONEL 625), UNS N10276(HASTELLOY C276),

|

|

ASTM/ASME B/SB160 UNS N02201(NICKEL 201), ASTM B/SB472 UNS N08020(Alloy 20)

|

|

Copper Alloy

|

ASTM/ASME B/SB151 UNS C70600(CuNi 90/10), C71500(CuNi 70/30)

|

|

Stainless Steel

|

ASTM/ASME A/SA182 F304,304L,304H,309H,310H,316,316H,316L,316LN,

|

|

317,317L,321,321H,347,347H

|

|

Duplex and Super Duplex Steel

|

ASTM/ASME A/SA182 F44,F45,F51,F53,F55,F60,F61

|

|

Carbon steel

|

ASTM /ASME A/SA105(N)

|

|

|

ASTM/ASME A/SA350 LF2

|

|

|

ASTM/ASME A/SA694 F52, F56 F60, F65, F70

|

|

|

ASTM/ASME A/SA182 GR F5,F9, F11,F12,F22,F91

|

|

|

ASTM/ASME B/SB381 Grade 2, Grade 5, Grade 7

|

Main Material:

Base: Carbon Steel, Alloy Steel, Pipeline Steel, etc. Lining: Stainless Steel, Duplex steel, Nickel-based Alloy, Titanium, Copper and other Corrosion - resistant Alloys.

Application Condition:

Widely used in Petrochemical, Coal Chemical, Refining, Oil and Gas Transmission, Marine Environment, Power, Heating and Other projects

Product Characteristics:

Adopts the patent technology make the material of two kinds of interference, ensure the working condition of medium in corrosion environment, meet the requirement of pressure, and greatly reduces the cost of materials, at the same time have a big binding

Our Company offers a variety of CRA clad or lined steel pipes including longitudinal seam clad steel pipe, helical seam clad steel pipe and seamless or welded lined steel pipe, and produces the corresponding elbows etc. in accordance with API Spec 5LD, DNV-OS-F101, SY/T6623 and CJ/T192. The products can be widely used in high corrosion environment, such as oilfield exploitation, oil and gas gathering and transportation, oil and gas transportation, corrosive medium transportation, petrochemical industry, pressure vessels, food industry, chemical fertilizer, pharmacy, sewage treatment, seawater desalination and drinking water etc., and are of high performance to price ratio.

CRA clad steel pipe:

Use hot rolling metallurgy composite plate or coil as material, modern advanced pipe-making technology (UOE, JCOE, COE and SAWH) to forming, SAWL or SAWH, and TIG etc. combined automatic welding process to complete welding. The welding quality is stable, and the product size accuracy is high. The composite plate or coil is manufactured by hot rolling technology, which can achieve metallurgical bonding of the atom between corrosion-resistant clad and the backing layer, the binding force reaches above 200MPa, the binding area rate can reach above 99.9%, and the performance is stable and reliable. The clad can meet the corrosion-resistant specific performance requirements, and the backing layer can meet the strength and rigidity condition the structure required.

Seamless or welded Lined steel pipe:

Seamless or welded carbon steel pipe as the outer backing layer, and corrosion-resistant alloy pipe as the inner corrosion layer, using the limit elasticity hydraulic composite method innovated independently by the company achieves the composite between the inner and outer pipe and forms the mechanical liner pipe. Through the composite technology, the optimal composite effect of mechanical liner can be achieved, and the shear stress between inside and outside metal layer can reach 2.0MPa (the relative standard requires 0.2-0.5MPa). Meanwhile, we develops specially the pipe ends automatic overlaying technology and NC machine tools specialized for beveling, which can process complex shape bevels such as U-bevel, and guarantees the conformity of pipe mouth diameter and bevel size, so as to operate pipe jointing on site.

PRODUCT MATERIALS

BACKING MATERIALS:

Q235B, Q345B, Q245R, Q345R, 16MnDR, L245~L485 (API 5L Gr.B, X42~X70), and other backing materials may be used according to user’s requirement.

CRA GRADES:

S30408 (TP304), S30403 (TP304L), S31608 (TP316), S31603 (TP316L), S32168 (TP321), S31803 (LC2205), S31260 (LC2506), N06625 (ASTM B443 625), N08825 (ASTM B424 825), and other corrosion-resistant cladding materials may be used according to user’s requirement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!