Products description:

Non asbestos gasket sheet with graphite coated and wire reinforced

Working pressure : 3~14 Mpa, Max working temperature: 150 ~ 450℃

This series include: JXB150,JXB200,JXB250, JXB350,JXB450.

Thickness: 1.0 to 6mm

4500 x 1500mm, 4100 x 1500 mm, 3850 x 1300 mm, 1270 x 1270 mm,

1500 x 2000 mm, 1500 x 1500 mm , 1500 x 1350 mm, 1500 x 1000 mm ,

The other size is optional or according to the requirements of customers.

Packing: in wooden pallet of about 1000 kg, 2000kgs net each.

Non asbestos gasket sheet

Thickness: 0.3~6.0mmAvailable

size:1500x2000mm,1500x1350mm,

1500x1000mm,1270x1270mm 1500x4100mm,1500x4600mm, 1310x3800mm.

OEM service : logo printing ,wire mesh insert and graphite coated

Package:

PALLET:1500-2000Kg per pallet

ROOLS: 50Kg per roll.

This series include: XB150,XB200,XB250,XB300,XB350,XB400,XB450,XB510.

With steel wire inserted and coated with graphite on the surface is applicable

Oil resistant non asbestos gasket sheet

Thickness: 0.3mm to 5mm

Available size:1500*2000mm, 1500 x 1500mm , 1500 x 1360mm, 1500 x 1000mm, 1270 x 1270mm.

The other size is optional or according to the requirements of customers.

At the same time, steel wire net inserted (coated graphite one side or two side) is available.

Packing: in wooden pallet of about 1000 kgs, 2000kgs net each.

This series include: NY150,NY250,NY300,NY400,NY510,HNY300

Reinforced non asbestos gasket sheet with wire mesh insert

Thickness: 1.0 to 6mm

4500 x 1500mm, 4100 x 1500 mm, 3850 x 1300 mm, 1270 x 1270 mm,

1500 x 2000 mm, 1500 x 1500 mm , 1500 x 1350 mm, 1500 x 1000 mm ,

The other size is optional or according to the requirements of customers.

Packing: in wooden pallet of about 1000 kg, 2000kgs net each.Working pressure : 3~14 Mpa, Max working temperature: 150 ~ 510℃

This series include: JXB150,JXB200,JXB250, JXB350,JXB450,JXB510

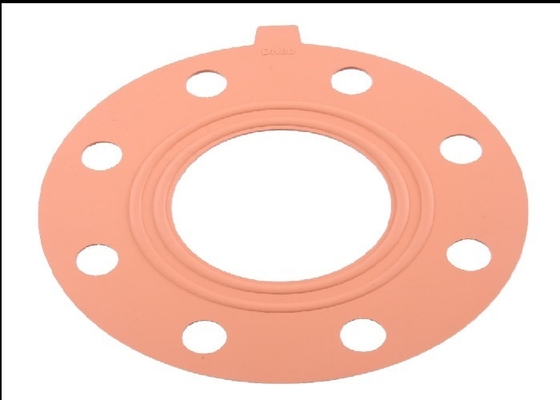

Non-Metallic PTFE With Hole For Plate Flat Face Flange Gasket Gasket O-RING Gasket

Non-Metallic PTFE With Hole For Plate Flat Face Flange Gasket Gasket O-RING Gasket

Material: PTFE(Non-metallic flat gaskets)

Size: DN100

Pressure Class: PN16

Thickness: 1.5MM

Manufacture Standard: EN1514-1, ASME B16.21

ypical Characteristics:

PTFE material has excellent resistance for all chemical corrosion. Its friction coefficient is the lowest in plastics.

Temperature changes do not affect its electrical insulation property. So PTFE often be called "plastic king". PTFE

is suitable for making corrosion resistant parts, wear parts, seal, insulation parts and medical equipment parts.

| 1.Usage: |

A. electrical insulation parts

B. sealing parts

C. automobile parts

D. corrosive fluid conduit

E. connector accessories

|

| 2.Best precision: |

0.02mm |

| 3.Surface: |

A. flat and tidy

B. no defects of crevices layers and separation

|

| 4.Temperature range: |

-196°C to +260°C |

| 5.Chemical property: |

A. aging resistance

B. radiation resistance

C. low permeability

D. high pressure resistance

E. oil resistance

F. anti-corrosion

|

Specifications:

1) We can supply many different kinds of rubber rings and gaskets

2) Materials include NBR, NR, SBR, IIR, EPDM, silicone, nitrile rubber and Vitonor

upon customers' requests

3) Rubber products have good water resistant, oil, high/low temperature resistant

properties and good tensile strength

4)Standard: BS4504 and BS2494 standards, or upon customers' requested standards

5) Special rubber gaskets and O-rings can be made according to customers' drawings

or samples

7) Widely used for sealing air, water or chemicals in machines from dust and oil

8) All manufacturing processes confirm to the ISO9001:2000 and ISO14001 standards

9) Excellent chemical and physical properties

10) Green product

11) Available in various sizes and colors

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!